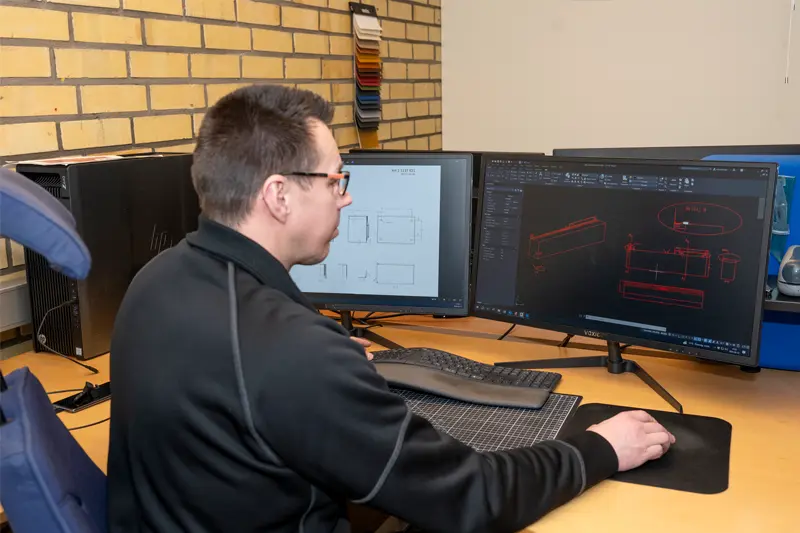

From idea to finished product

Lindevalls' product developers have extensive experience in developing new products within industrial sewing, such as bags, cases, harnesses, seals, and insulation. We have both the expertise and capacity to handle complete development projects from requirements gathering to development, drawing production, and validation.

Lindevalls has completed numerous development projects for several leading Swedish industrial companies. From the customer's requirements and specifications for the finished product, we develop construction proposals and suggest both materials and manufacturing processes. If needed, prototypes are quickly produced for evaluation before serial production begins.

Lindevalls can produce complete construction documentation such as material specifications, manufacturing documentation, and drawings without production being tied to the project.

In an initial meeting, Lindevalls aligns with the customer on the project's prerequisites, both for the product itself, the documentation to be produced, whether prototypes should be produced, and the schedule. Lindevalls then provides a cost proposal to the customer.

Once the prerequisites are agreed upon, a responsible product developer is appointed for the project. The product developer begins by gathering the information needed to produce the documentation requested by the customer.

During the development project, the product developer needs to consult with the customer on any questions that arise. When the project is completed, documentation and any prototypes are handed over to the customer.

Lindevalls Industri AB

Voltvägen 32B

831 48 Östersund

Sweden

Phone: 063-57 75 70

E-mail: mail@lindevalls.se

Facebook

LinkedIn